Sjálfvirk þvottakerfi

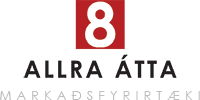

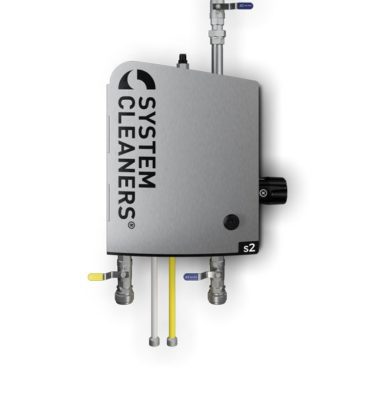

Slík kerfi eru notuð víða í matvæla og iðnaðarfyrirtækjum við þrif á vinnslustöðvum. Notkun sjálfvirkra þvottakerfa auðveldar öll þrif við vinnslu matvæla og vinnslustöðva. Kerfið er þróað til að hreinsa og sótthreinsa færibönd og vinnslur, en auðvelt er að sérhanna kerfin að mismunandi hönnun og kröfum fyrir hvern og einn. Kerfið er sjálfvirkt, en með því að nota slík kerfi er hægt að spara tíma og auðvelda ferla.

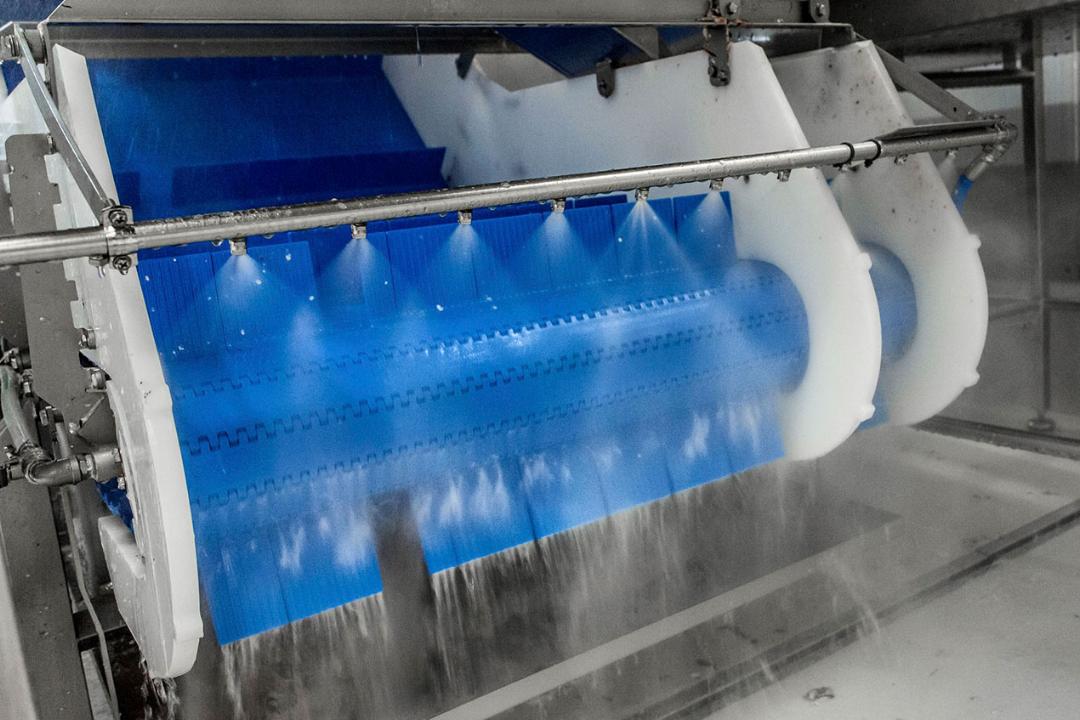

Spreybar eru settar á ákveðnum stöðum til að tryggja að allt beltið sé hreinsað og sótthreinsað til að koma í veg fyrir vöxt örvera.

Kostir sjálfvirks hreinsunarkerfis eru m.a.:

- Bætir hreinlæti og matvælaöryggi

- Árangursrík og kerfisbundin hreinsun

- Nær til dökku svæðana á beltinu, sem erfiðara er að komast að til að þrífa

- Kemur í veg fyrir mengun og vöxt örvera

- Minnkar tíma sem tekur að þrífa verulega – eykur framleiðslutíma

- Minnkar kostnað